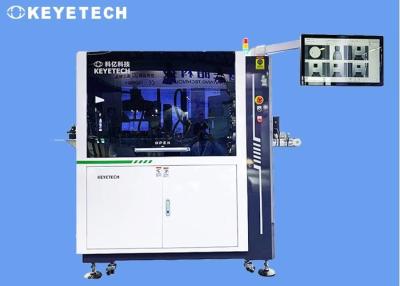

Machine d'inspection optique automatique pour accessoires de l'industrie du plastique médical

Jul 03, 2025

15 vues

# Machine optique automatique de l'inspection SS304

# Machine optique automatique d'inspection d'industrie textile

Machine d'inspection optique automatique pour accessoires de l'industrie du plastique médical

Avantages du système

1. Test sans contact et non destructif, n'endommagera ni ne rayera le produit.

2. La vitesse est rapide, ce qui peut correspondre à la vitesse de la chaîne de production sans retarder le temps de production.

3. L'efficacité de la détection est élevée, le taux de précision de détection des produits est élevé et les défauts de détection manquée et de fausse détection dans la détection manuelle sont améliorés.

4. Fonctionne 24 heures sur 24 pendant une longue période, sans fatigue visuelle, travail stable et efficacité de travail élevée.

5. Le coût de la main-d'œuvre est réduit, et l'inspection par vision artificielle permet d'économiser beaucoup de coûts de main-d'œuvre, ce qui apporte des avantages considérables à l'entreprise.

6. Forte applicabilité et grande flexibilité, adapté à diverses vibrations, humidité, poussière et autres environnements difficiles.

Profil de l'entreprise

Anhui Keye Intelligent Technology Co., Ltd. est une entreprise nationale chinoise de haute technologie spécialisée dans l'application de la technologie d'IA dans l'industrie de l'inspection visuelle. En tant que fabricant et concepteur de premier plan, elle peut fournir l'équipement d'inspection visuelle d'IA le plus avancé et les solutions de système d'IA personnalisées d'imagerie visuelle, de puissance de calcul, d'algorithme et de logiciel de contrôle automatique pour diverses sous-industries.

L'entreprise a été créée en 2011, elle dispose d'une équipe de R&D de haut niveau issue des meilleurs instituts de recherche optique nationaux et d'une équipe de doctorants de l'USTC, couvrant l'ensemble de la chaîne technologique de l'optique, de l'électricité, de la mécanique, de l'algorithme et des logiciels. Nos produits peuvent être appliqués dans les industries de l'emballage des boissons, de la pharmacie, des produits laitiers, du vin, du textile, des nouvelles énergies, de l'agriculture et autres.

Principe d'inspection

Avec le développement continu de l'industrie de l'habillement, le rôle des boutons ne se limite pas seulement à relier l'empiècement des vêtements, mais développe également des caractéristiques plus artistiques et décoratives, qui jouent un rôle plus important dans le sens du design et de la qualité des produits vestimentaires. Si la qualité des boutons n'est pas conforme aux normes, l'ensemble du produit, voire l'ensemble de la marque textile et vestimentaire, peut être impliqué.

Les boutons sont produits en grandes séries, et certains petits défauts de surface sont facilement négligés par les travailleurs. Ces problèmes peuvent être évités en remplaçant l'inspection manuelle par un équipement d'inspection par vision artificielle des boutons et en détectant automatiquement les défauts de surface des boutons.

Détails de l'inspection

L'équipement d'inspection par vision artificielle des boutons est automatiquement alimenté vers la plate-forme d'inspection par la plaque vibrante, et la caméra CCD industrielle prend des photos des produits en mouvement à grande vitesse, puis le système logiciel d'inspection par vision artificielle Haotianchen effectue une inspection en temps réel à grande vitesse, haute précision et haute stabilité des images photographiées. , analyser, calculer, juger si l'échantillon est qualifié, puis sortir et compter les résultats, et retirer automatiquement les produits défectueux.

(Face avant)

En utilisant plusieurs stations, l'équipement peut détecter automatiquement les défauts sur la surface des boutons de manière globale. Les défauts qui peuvent être détectés comprennent la longueur, le diamètre extérieur et d'autres défauts dimensionnels, un mauvais placage, des rayures, des fissures, des bavures, des dommages, des trous, de la saleté, etc. En cas de défauts d'apparence, il peut également identifier, lire et détecter le logo, les caractères et autres informations d'identification sur la surface du bouton.

(Face arrière)

Service après-vente

L'entreprise dispose d'une équipe de service technique complète et d'un mécanisme de réponse rapide, et dispose de spécialistes de service dédiés pour chaque client, qui peuvent recevoir des consultations techniques et des rapports de panne des clients à tout moment. Et pour assurer une réponse rapide aux urgences des clients, pour garantir que les clients reçoivent un service satisfaisant. Pendant l'épidémie ou pour des raisons particulières, lorsque les ingénieurs après-vente ne peuvent pas se rendre sur le site, le centre de service peut ajuster à distance l'équipement du client pour le dépannage et la consultation technique.

Après l'arrivée de l'équipement chez le client, l'ingénieur après-vente arrive à t

Apprendre encore plus →

-

Machine de tri visuel pour le contrôle qualité de pièces moulées par injection plastique

Voir les détails -

Machine d'inspection optique automatique pour accessoires de l'industrie du plastique médical

Voir les détails -

Machine d'inspection visuelle AOI de fermeture de bouchons en plastique pour l'industrie agroalimentaire

Voir les détails -

Machine d'inspection des bouteilles à goutte vide avec écran tactile HMI

Voir les détails -

Machine d' inspection de bouteilles vides de 75 ml à 100 ml avec le dernier algorithme d' IA

Voir les détails -

Machine de classement de noix de noix de noix de qualité supérieure avec 3 à 8 ports de rejet

Voir les détails -

Machine d'inspection de la vision de fermeture de la capuche de CR CT Pharma basée sur un algorithme d'IA

Voir les détails